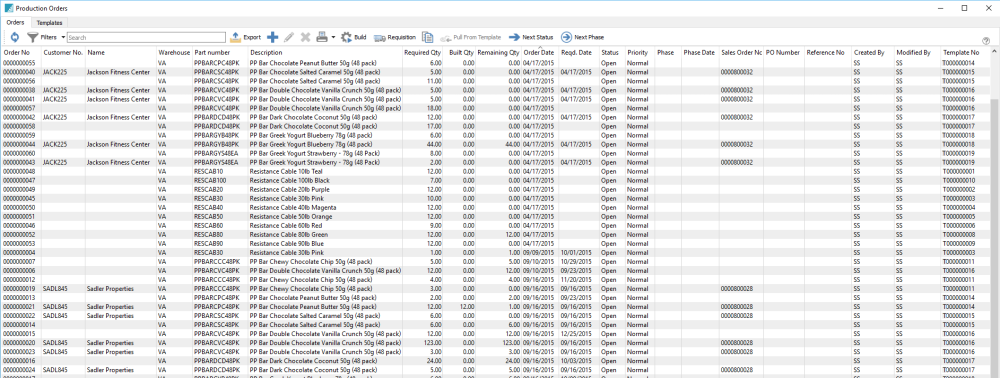

Production Order list

Refresh – Refreshes the list of production orders for changes that others have made.

Filters – Sets filters to see just the production orders required.

Search – Enter the word(s) to find info from the header or details of production orders.

Export – Exports the filtered list to Excel or .csv.

Add – Adds a Production Order

Edit – Edits a Production Order

Delete Deletes selected production order(s).

Print – Prints selected Production Order(s).

Build – Builds selected Production Order(s) to receive the finished product using the total component cost, and relieves the components from inventory.

Requisition – Requisition shortages for selected Production Order(s).

Copy – Copies a Production Order to a new one.

Pull From Templates – Pulls details from the template from which the production order(s) were derived. This is useful to update the production order if the template has been edited.

Next Status – Moves the selected production order to the next status.

Next Phase – Moves the production order to the next phase based on the custom phases setup in production.

Order No – The sequence number assigned to the production order. It gets the next sequence from Company Settings/Sequence numbers.

Customer No – The customer that this production order is for. It can be added manually or it can come from sales orders when a user requisitions a manufactured item.

Name – The name of the customer the production order is for.

Warehouse – The warehouse where the item will be ‘Built’ into.

Part Number – The part number of the item that will be built.

Description – The description of the item that will be built.

Required Qty. – The quantity that is required to be built. This can be entered manually or can come from the shortage on a sales order when requisitioned.

Built Qty – The quantity that has been built so far on this production order.

Remaining Qty – How many are left to be built on this production order.

Order Date – The date the order was added.

Reqd. Date – The date that is required fore this production order to be completed. This date is either added manually or will come from the required date of a sales order requisition.

Status – The status of the production order.

- New – This means the components of this production order are not yet committed in inventory.

- Pending – The components are now committed and this usually means that production has not yet started.

- In Progress – The components are committed and the work is now in progress.

Priority – Users can set a priority so that they can sort by this to see the most important ones, or derive a report based on priority.

Phase – What phase the production order is currently in.

Phase Date – The date that this production order was moved into its current phase

Sales Order No. – The sales order number that this production order is from. This can be manually entered or come from sales order requisitions.

PO Number – The customers purchase order number.

Reference No – A reference number that gets manually entered.

Created By – The initials of the user that created this production order.

Modified By – The initials of the user that last modified this production order.

Template No – The template number that this production order was derived from. If this is blank it means that it was created as a custom order from the start. A production order can become a template for later use.