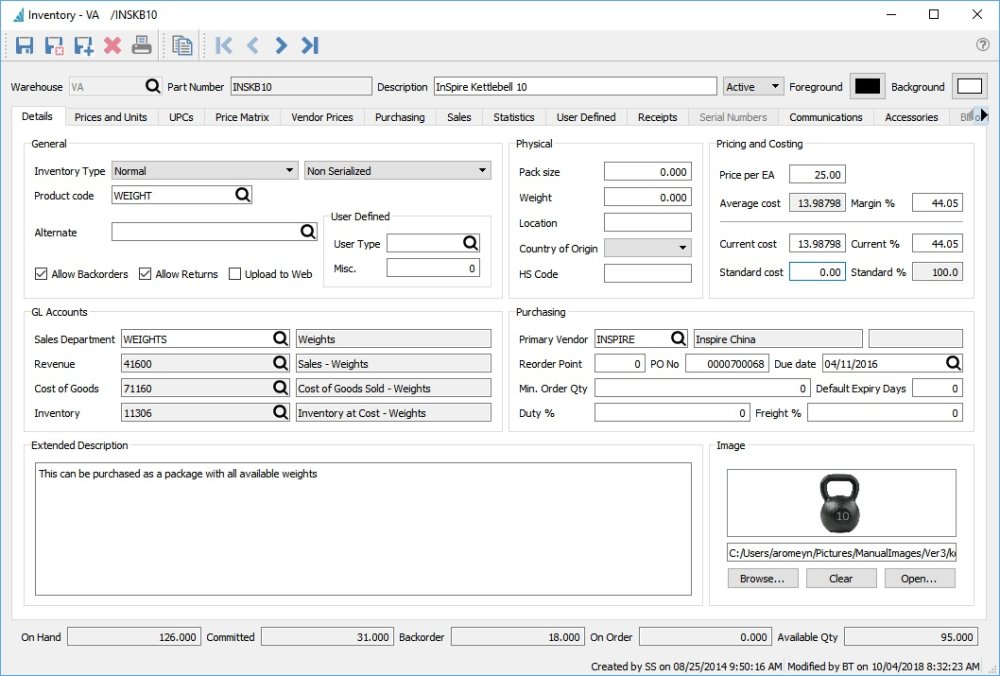

Inventory Header

![]()

Warehouse – The warehouse that this item is in. This will not appear if warehousing is not turned on in company settings

Part Number – This items code

Description – This items description

Status – The status of the item. Can be set to:

- Active

- Inactive

- On Hold

Foreground Colour – The foreground or text colour of an item. The colors are user configured for any purpose the company requires. For instance items that are discontinued can be green.

Background Colour – The background colour of an item.

Save – Saves and keeps the item open

Save/Close – Saves and closes the window back to the main inventory list.

Save/Create New – Saves current item and starts new one

Delete – Deletes the item if there is none on-hand, back ordered, committed or on-order

Print – Prints reports related to this item

Copy – Copies the item allowing user to edit the warehouse and part number before saving.

Navigation Arrows – Navigates between inventory records keeping the list filtered and sorted as it was when the item was edited.

General

Inventory Type – Inventory items can be set as:

- Normal – For normal buy/sell items

- Non-Physical – For items that are not physically in inventory. Use this for things like labor or miscellaneous items that belong in a particular sales department. Use caution with cost on non physical items. Be sure that the sales department used does not credit the inventory GL account, unless the user makes sure that an corresponding AP entry gets debited to the inventory asset account.

- Manufactured – For items where a template is created to deplete raw material items from stock when building and receiving the finished product into stock. The build process will credit inventory raw material and debit inventory finished goods, if their sales departments are different.

- Kitted – Items that are built ‘on-the-fly’ then invoiced to a customer. When a kit is added to a sales order it commits the components in inventory. When the order gets invoiced the components are depleted from stock and the kit is put into stock and then immediately removed as the invoice is posted. See this link for full description

- Raw Material – Treated the same as normal items. The only reason for a different type is that some companies want to see raw material separately in stock from normal items.

- Macro – Replaces the item that is sold with a selection of other items. See this link for full description

Serial/Lot – Inventory items can be set as serialized or lot controlled. When serial numbers are received into stock each serial number has a quantity of 1. Lot numbers can be received with many to the same lot number. When the item is added to a sales order the user is presented with the serial/lot number(s) to select. For more details on Inventory Lot Control See this link.

Product Code – This is used to group common inventory items together. The product code can be related to ‘Sales Dept’ so that when an items product code is edited the related sales department is also changed.

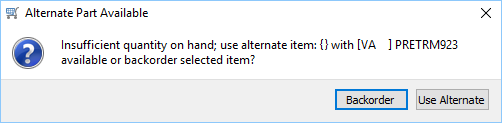

Alternate – Sets an alternate inventory item so that if an item is out of stock and it is added to a sales order the user is prompted if they would like to replace it with the alternate, or to back order the item that is short. This is also useful if the item has been replaced and the user accidentally uses the old part number.

Allow Backorders – If unchecked this item cannot be back ordered.

Allow Returns – If unchecked this item cannot have a negative quantity shipped.

Upload to Web – A setting used by 3rd party developers to indicate if item should be in the web store

User Defined

User Type – This alphanumeric field can have its label defined in Company Settings/Variables and has a lookup tables associated with it.

Misc. – This numeric field can have its label defined in Company Settings/Variables

GL Accounts

Sales Department – The name describing the type of item being sold.See ‘Sales Dept’ in company settings.

Revenue – GL account where the revenue posts to

Cost of Goods – GL account where cost of goods post to

Inventory – GL account where inventory is relieved from

Physical

Pack Size – The standard pack size that an item is bought and or sold in. This field appears on the sales order line to encourage the salesperson to sell full packs, but does not warn or use full packs automatically.

Weight – The weight of the stocking unit of measure for this item

Location – The location of this item in inventory.

Country of Origin – The country where an item came from that needs to go onto an international bill of lading.

HS Code – The harmonized system customs code that may need to go onto an international bill of lading.

Pricing and Costing

Price per – Sell price 1 and its unit of measure

Average Cost – The average cost of an item based on receipts of items. This is the default method of costing and is the most common used

*Margin % – The margin between average cost and sell price 1

Current Cost – What was last paid for an item or what the user edited the cost to. If the on-hand quantity is zero and the user edits the current cost the average cost will get the same value.

Current % – Percentage between current cost and sell price 1

Standard Cost – A cost that only changes if the user sets it. This is commonly used to inflate the cost by adding overhead to it. This cost can be used to post to sales history instead of current cost in company settings/Sales Orders/Process/Post Standard Cost to Sales History Current Cost.

Standard Cost % – Percentage between standard cost and sell price 1

Purchasing

Primary Vendor – The vendor that the item is usually purchased from.

Reorder Point – How many are required to be in stock for this item. The reorder point is used to calculate the ‘Suggested Order Qty’

Min. Order Qty – The minimum the supplier will sell. This is used in the ‘Suggested Order Qty’

Duty % – The usual duty charged on this item. This field is editable, and if the ‘Save Landed Cost’ is turned on in Company Settings/Inventory this will be updated when receiving a purchase order and the user has edited it on the PO line.

PO Number The last purchase order number issued for this item. This field is editable.

Due Date The due date of the last purchase order issued for this item. This field is editable.

Default Expiry Days – When an item that is lot controlled is received this number is added to the receive date to calculate the expiration or best before date.

Freight – The usual freight charged on this item. This field is editable, and if the ‘Save Landed Cost’ is turned on in Company Settings/Inventory this will be updated when receiving a purchase order and the user has edited it on the PO line.

Extended Description

Extended Description – A long description an be added here for this item. It can be printed on sales reports and invoices. There is a sub report for this purpose on the Spire stock reports but is hidden by default. Contact your Spire partner if you do not have the knowledge to edit this.

Image

Image – An image can be browsed and attache to thei item . Be sure to use a location that can be accessed by all users or else they will not see the image. This image is showed each time the item is sold in POS

Quantities

On-hand – Quantity on-hand of this item. It includes all committed items.

Committed – Quantity that are committed on sales orders, production orders and inventory adjustments/transfers in transit.

Backorder – Quantity on back order on sales orders.

On Order – Quantity on issued purchase orders not yet received.

Available – On-hand quantity minus committed quantity.