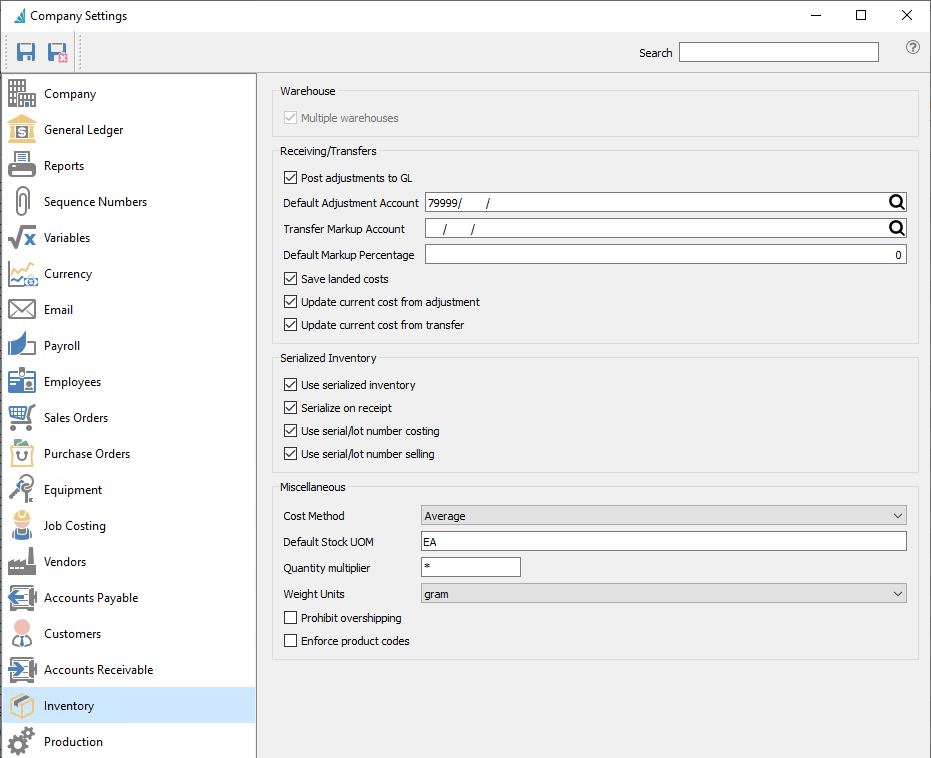

Warehouse

Multiple Warehouses – Select if you require more than one warehouse. Once warehouses are created, this option cannot be disabled.

Receiving/Transfers

Post adjustments to GL – When adjustments are posted, a transaction will be created in the General Ledger.

Default Adjustment Account – When adjustments are posted, this is the default Ledger account used as the offset to the Inventory account for the transaction. It can be edited on each adjustment detail prior to posting.

Transfer Markup Account – If a markup is required when transferring inventory, then the markup amount will be posted to this Ledger account, calculated from the Markup % on the transfer. Typically a sales account is used here. Posting will debit the inventory account defined on the receiving warehouse and credit the sales transfer markup account.

Default Markup Percentage – The default percentage used for marking up inventory transfers if an account is selected above.

Save Landed Costs – Automatically save the Freight and Duty/Brokerage percentage values entered on a purchase order detail to the respective inventory record, for use in future purchase orders.

Update current cost from adjustment – If an Inventory Adjustment is posted with a change in Current Cost of an Inventory item it will update the Current Cost on the Inventory record

Update current cost from transfer – If an Inventory Transfer is posted with a change in Current Cost of an Inventory item it will update the Current Cost on the Inventory record

Serialized Inventory

Use Serialized Inventory – Use either serial numbers and/or lot numbers for tracking items, either for maintaining tight control of serial/lot numbering throughout the purchasing, producing and selling stages, or just for entering numbers on sales orders.

Serialize on Receipt – Enable for Serial numbers and/or Lot numbers to be assigned to inventory items when they are received, which in turn can be selected when the items are sold, transferred or adjusted. This must be enabled for the Use serial/lot number costing and selling options to be available for selection. This also must effectively be enabled if Manufactured components use serial/lot numbers, because Building inventory will not prompt for new numbers. When this option is disabled, serial/lot number entry is disabled within purchase orders and all other transactions, and can only be entered for sales order shipping.

Use serial/lot number costing – Costing for sales history and GL transactions will come from the individual serial/lot number instead of the inventory item, as determined when the item is received or produced. On Sales Orders, having multiple serial/lot numbers with different costs on a single detail will calculate the required unit cost in order to determine the correct total Cost of Goods sold.

Use serial/lot number selling – The Sell price on sales orders will come from the individual serial/lot number instead of the inventory item. Serial/Lot sell prices are completely independent from values determined from inventory price levels or Price Matrix, and do not change if inventory price levels change. Multiple serial/lot numbers with different sell prices should not be combined on a single sales order detail, because the individual prices will be lost.

Miscellaneous

Cost Method – Choose Average or FIFO, or LIFO if the company address is in the US. Using Average costing means that invoicing Sales Orders determines the cost of sales based on the calculated average cost of all items purchased. Using FIFO (First In, First Out) costing means that invoicing Sales Orders determines the cost of sales based on the unit cost of the oldest PO receipt, depending on the Remaining quantity on these receipts. Using LIFO (Last In, First Out) costing means that invoicing Sales Orders determines the cost of sales based on the unit cost of the newest PO receipt. Costs within FIFO or LIFO handling will be different only if stock on hand was received in multiple purchases that had different unit costs.

Default Stock UOM – When adding a new item to inventory it will default to this unit of measure.

Quantity multiplier – The user can use a shortcut character to multiply an item in POS. ie. if the multiplier is set to * then when 6 of an item are required the user would enter 6* and then scan or type the item.

Weight Units – Display a unit of measure label next to the Weight field, for reference only and not used for calculations.

Prohibit overshipping – Inventory cannot be consumed below zero on hand.

Enforce Product Codes – Require product codes when adding inventory items.